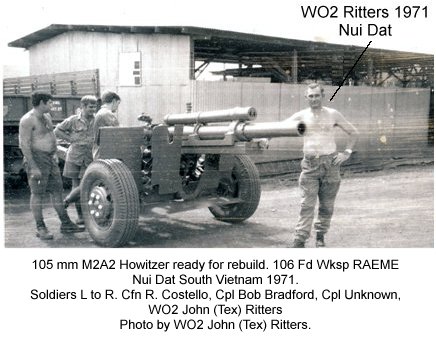

REBUILD OF 105mm M2A2 HOWITZERS

BY 106 FD WKSP RAEME

NUI DAT SOUTH VIETNAM 1971

In March 1971 I was then the Pl Comd of the GE Pl at 106 Fd Wksp with a mixed platoon of Regulars, Nasho’s and a bevy of WO’s; some filling lower rank positions. This combination of Regular/Nasho’s & experienced senior ranks gave us a trade base better than would usually be expected in a fi eld workshop. Of particular benefit was an experienced National Serviceman welder whose rebuild of mine damaged M113 hulls was exceptional.

Work progressed at the usual hectic pace of a Fd Wksp; compounded by the variety of equipment not normally found in a Task Force, e.g. Topographical Survey map making equipment, Battle Intelligence PDP11 computer, SAS ‘specials’ etc, the effect of the tropics on equipment and the increased repair load as the Task Force prepared to withdraw later that year and the Kiwi’s wanted all equipment Serviceable before departure as they said things were much tighter back home. Watching a very BER wreck of an International 2 ½ ton truck issued to the Kiwi’s blown up instead of repaired brought joy to my heart (and a scramble to take cover under an M113 APC as the 4RAR/NZ Assault Pioneers had used up all their surplus explosives and truck parts were scattered over more than 1,500 m radius – very naughty and brought a reprimand from HQ 1 ATF)1.

In March 1971 the OC (the late then Major John Sinclair, pictured) returned from a 1 ATF Commanders Conference with urgent orders; apparently the CO 12 Fd Regt RAA (the late then Lt Col Bruce Topfer) had advised the Comd 1 ATF that the Regt could no longer fire safely “Danger Close” missions (first round no closer than 1,000m to leading elements of ground troops) because of the poor state of his guns. The OC told me that the 1 ATF Comd had directed that 106 Fd Wksp was to attend to the guns as a top priority and I was to undertake a quick inspection to scope the problem.

In March 1971 the OC (the late then Major John Sinclair, pictured) returned from a 1 ATF Commanders Conference with urgent orders; apparently the CO 12 Fd Regt RAA (the late then Lt Col Bruce Topfer) had advised the Comd 1 ATF that the Regt could no longer fire safely “Danger Close” missions (first round no closer than 1,000m to leading elements of ground troops) because of the poor state of his guns. The OC told me that the 1 ATF Comd had directed that 106 Fd Wksp was to attend to the guns as a top priority and I was to undertake a quick inspection to scope the problem.

Taking Sgt John Loch (Gun Artificer) in tow we proceeded to the 12 Fd Regt gun positions and quickly looked over the troop of guns that were available. There was no need to strip anything to determine serviceability; when you could lift the gun muzzle 60 mm and rock it left & right 75 mm it was obvious that the wear was in excess of the EMEI limits and firing inaccuracy would result. With the gunners’ approval we took one gun back to the workshop for more detailed inspection and we showed the OC the obvious wear. More detailed inspection of the gun showed that the wear was through all systems of the gun with solidified grease & water in the wheel bearings; axle shafts hammered oval; grit & water in gear boxes; grit & dust within the recoil slides etc. Later discussion with the LAD brought the comment that Regt officers complained if grease was oozing out of slides etc “as it collected dust”. They obviously didn’t understand that regular greasing forced the dust & water out.

This all indicated a lack of operator maintenance but just as worrying, a failure by the EME system to provide the necessary technical inspection and advice to the user. Maj. John Sinclair later advised me that the proposed in-country Equipment Inspection Service (EIS) manpower had been used for the establishment of 106 Fd Wksp and consequently the function was never implemented.2 Just prior to my posting to SVN I undertook an “Officers Small Arms Repair Course” at RAEME Trg Centre that was quickly arranged because of continuing serviceability problems with small arms in SVN; the condition of the guns indicated that these problems obviously extended to more than just small arms.

In early April we continued on with the inspection of the guns and found that they were all nearly in the same condition; even the two guns from 1AOD Vung Tau were in similar, if not worse condition, and unfit for issue. Why they had never been returned to Australia earlier for overhaul I never found out. We were informed by John that replacement guns were not available from Australia and there were severe serviceability problems in Australia with a lack of key parts. The US Army had apparently also advised HQ AFV that they had no guns available and as the M2A2 had been declared obsolete Australia could source what spares they had. We were later to discover that a quantity of obsolete self-propelled (tracked) M2A2’s were in the US Long Binh stores depot; their computer system didn’t report this because of their obsolete status. 3

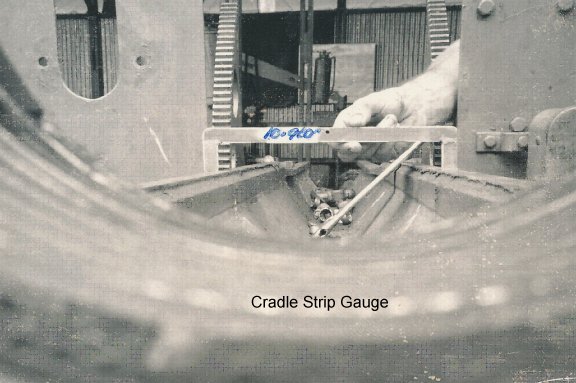

The pressure was then on RAEME and RAAOC to find a solution quickly. After quick detailed inspection of one gun and confirmatory inspection of several others I reported to Maj. John Sinclair that we could overhaul the guns provided parts were available and that the problem of machining the long recoil slides could be solved (brass strips riveted onto the cradle and then machined to suit the barrel/recoil sleigh). Picture Cradle Strip Gauge One item that was critical was the axle assemblies; the stub axles (maintainable item) were shrunk & welded into the axle trees and we had no means of replacing the stub axle or repairing the ovality. In the event, the US system had stocks of axle assemblies and the worn items were returned to Australia as Repairable.

The pressure was then on RAEME and RAAOC to find a solution quickly. After quick detailed inspection of one gun and confirmatory inspection of several others I reported to Maj. John Sinclair that we could overhaul the guns provided parts were available and that the problem of machining the long recoil slides could be solved (brass strips riveted onto the cradle and then machined to suit the barrel/recoil sleigh). Picture Cradle Strip Gauge One item that was critical was the axle assemblies; the stub axles (maintainable item) were shrunk & welded into the axle trees and we had no means of replacing the stub axle or repairing the ovality. In the event, the US system had stocks of axle assemblies and the worn items were returned to Australia as Repairable.

102 Fd Wksp Vung Tau was contacted and asked to investigate machining options as we believed that the helicopter repair ship USS Corpus Christi had a heavy machining capability; this turned out not to be an option however 102 Fd Wksp found that the US Air Base in Vung Tau had a large milling machine and the Wksp could access it “after-hours”. This machine didn’t have the required bed length so the workshop developed a “work-around” by machining the lengths in two serial operations and then hand finishing the strips with body files to suit the particular cradle.

I was asked to develop a rebuild project; estimate the duration and manpower required. This I did & Maj. John Sinclair took up the options with HQ 1 ATF, HQ AFV, MGO Branch & DEME. From what I understood at the time, the concerns that Australia had regarding 106’s ability to carry out the project didn’t seem to worry the Comd 1 ATF as Australia couldn’t do anything about replacing/repairing his guns and there was an urgent need to regain accurate gunfire support. His confidence in his workshop was edifying to us but also very worrying because of the technical concerns we had.

Maj. John Sinclair questioned me very thoroughly on how we would carry out the project and I identified the risk areas and explained how we intended to overcome them and what support we would need from stores supply & 102 Fd Wksp who seemed reluctant to take on the machining task. I was very aware then from conversations with the C.O. that MGO Branch & DEME were very concerned that 106 Fd Wksp could undertake such a project but the ADEME & ADOS from HQ AFV had visited us and offered all the support possible and so he then advised Commander 1 ATF we could do the project. In later years I was to find out that Maj. John’s decision clearly put his career on the line as he received a “please explain” from MGO Branch where apparently it was not believed that a Fd Wksp could succeed where our Base Wksp’s had failed.

In coming to my advice that we could undertake the project, not only was I supported by some good artificers and tradesmen, in-country RAAOC stores officers (the OC of the Wksp Stores Section Lt Tony Stafford was a 17th intake Army Apprentice) & NCO’s that chased up parts listed & not-listed by the US stores system but also by the excellent & broad based training that I received on the Junior Officers Course at RAEME Training Centre. We spent twelve months there ex-Officer Cadet School; spending time in each Wing under the tutelage of experienced WO & Sgt instructors who saw it as their privileged duty to guide us upstarts in the ways of the technical world. It was there that we partially stripped guns such as the M2A2 and learnt about their characteristics and problems. Such knowledge and experience allowed us in later years to converse with and gain the confidence of our Artificers. I pity the young officers of the modern era who don’t get such a valuable introduction to the technical world of RAEME.

The Commander 1 ATF, with agreement from HQ AFV, ordered the workshop to overhaul the Regiment’s guns and gave us fifty days to do it. With the withdrawal of the New Zealand 161 Battery; we had an increased pool of guns in mid-April to draw on and allow the Fd Regt to continue providing fire support to the Task Force. At about this time the gun tools and the majority of the initial order of repair parts had arrived.

The two guns from 1 AOD Vung Tau were delivered to the workshop to start the project and stripping began. We were offered additional manpower if we needed it but I rejected this based on initial planning but took up the offer of WO2 John “Tex” Ritters (HQ 1ATF Armourer) ex 4 Fd Regt as a valued adviser on technical aspects. He was very helpful in the design of gauges for the fitting of the brass recoil slides.

As we progressed with the project and stripped more guns we identified more work to be done and we discovered more parts needed to be replaced and therefore started to run the supply system out of parts. This meant more bushes etc needed to be manufactured and therefore acquiring phosphor-bronze stock became a priority. This became a problem in our remote location and so, after some textbook research, several bushes were manufactured in brass and the Gun History Book’s annotated for these guns to have regular inspections and the bushes replaced when available. Not only was the gun rebuild team working long hours and six & a half days per week but the unit lathe was working each night until the RAE power generator shut down at 2200 hrs.

The cradle bearing strips machining method and the hand finishing gave rise to some very tight cradle/sleigh fits as stresses released during transport of matched cradles & sleighs by truck from Vung Tau to Nui Dat and I was faced with a decision on one very tight fit on a gun urgently needed (we believed that this may have been due to irregularities in the compression of the individual rivets (done by hand) but this couldn’t be proved). After pulling back the ordnance by hand (several times I remember) and checking the run-out, the gun was released to the gunners with the recommendation to fire the first round on charge one under EME supervision and regrease the slides between the first few rounds. All went well and the gun was back in action.

We delivered the first battery’s worth of guns and then a gunner’s problem arose; they were trying to “calibrate’ the guns using the “fall-of-shot” method but were having no success.4

An offer of RAEME assistance was rejected and the loan of a velocity measuring Doppler Radar & operator

from the US Army was arranged by the gunners. This equipment failed when deployed and we suspected connection problems but the US wouldn’t allow our electronics tradesmen to touch the system and it was returned. An urgent request went to Australia for the very new EVA (Electronic Velocity Analyser) equipment and it arrived with 2Lt Tony Ayerbe, Sgt Keith Ayliffe & Bdr Mick Kinang. The electronic measurements appeared to go OK including some taken on guns at a FSB but the conversion of these velocity measurements to gun correction factors posed some problems that had to be solved by the EVA team. (Pictured) I was present when the resident Nui Dat battery fired its’ first battery salvo to check the correlation of the individual gun’s impact points. The target was 8,000 m out with an FO observing in a 161 Recce Flt helicopter. When the FO returned I questioned him as to the results and he told me that there was a problem; the entire Battery’s rounds had impacted in a 25m circle which was too tight! I informed him that this was now an Artillery problem not a RAEME problem.

An offer of RAEME assistance was rejected and the loan of a velocity measuring Doppler Radar & operator

from the US Army was arranged by the gunners. This equipment failed when deployed and we suspected connection problems but the US wouldn’t allow our electronics tradesmen to touch the system and it was returned. An urgent request went to Australia for the very new EVA (Electronic Velocity Analyser) equipment and it arrived with 2Lt Tony Ayerbe, Sgt Keith Ayliffe & Bdr Mick Kinang. The electronic measurements appeared to go OK including some taken on guns at a FSB but the conversion of these velocity measurements to gun correction factors posed some problems that had to be solved by the EVA team. (Pictured) I was present when the resident Nui Dat battery fired its’ first battery salvo to check the correlation of the individual gun’s impact points. The target was 8,000 m out with an FO observing in a 161 Recce Flt helicopter. When the FO returned I questioned him as to the results and he told me that there was a problem; the entire Battery’s rounds had impacted in a 25m circle which was too tight! I informed him that this was now an Artillery problem not a RAEME problem.

It is interesting now at this late date to read the history of the “104th Fd Bty RAA VIETNAM 1968 – 1969 & 1971”5 to read “During this tour (1971) the infantrymen of 4RAR/NZ came to have such confidence in the 104th Field Battery that the Task Force Standing Order, stating that the 1st round of a Fire Mission had to be directed 1,000m in front of the leading elements, was waived for the first time. And, as a mark of affection, the infantrymen of 4RAR/NZ began to refer to the battery as “104 Company”.” We knew that the guns were performing well but I do not recall us ever getting such superlative feedback whilst in country. Certainly the Commander 1 ATF was pleased and so was the CO 12 Fd Regt RAA, Lt Col Topfer. Some feedback from the 12 Fd Regt LAD was that after the rebuild, Lt Col Topfer had assembled his Gun Sergeants and gave them a lecture on the maintenance of his guns and words to the effect that he would have new Gun Sergeants if they failed to heed the advice of their Gun Fitters. Much appreciated by the LAD and 106 Fd Wksp!

The project concluded later than the fifty days allocated by the Comd 1ATF but

106 Fd Wksp delivered sixteen guns (sufficient for the Regt) by the end of June and the remaining six guns on17 July. There was a break in production in late June/early July caused by lack of parts. The two key elements in the rate of output of the guns was the availability of cradles from 102 Fd Wksp with new brass sliding strips fitted and the supply of repair parts. The rebuilt guns were delivered with worn, but within specification barrels, but nearly every other sub-system was to original specification. The guns were repainted and, as per EMEI’s, a brass plate was affixed to each gun detailing the rebuild by 106 Fd Wksp. In about mid 2008 I received a phone call regarding research into the guns defending FSB Coral where one gun was overrun by the enemy and one had been hit by enemy fire and the recoil system damaged. The research had revealed these brass plates on the guns suspected of being at FSB Coral and it was thought that the rebuild was associated directly with the FSB Coral action. I was able to tell the researcher that, although the rapid firing at FSB Coral would have contributed to the need for rebuild, the rebuild did occur much later than 1968. One of these FSB Coral guns now stands at the School of Artillery, Bridges Barracks, Puckapunyal and another at the Australian War Memorial.

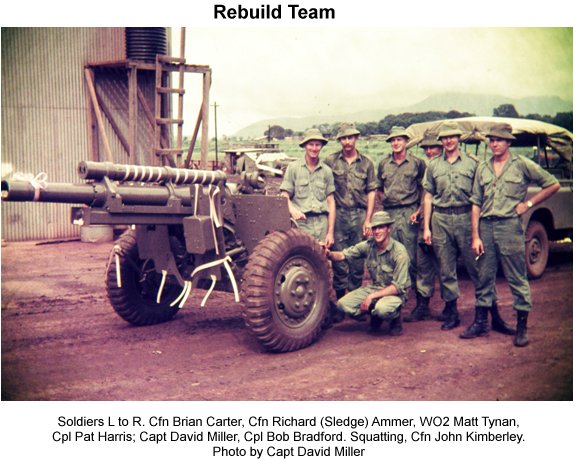

MEMBERS INVOLVED

106 Fd Wksp RAEME

- Major John Sinclair OC 106 Fd Wksp

- Capt David Miller OC GE Pl

- Lt Tony Stafford OC Stores Section RAAOC

- WO2 Matt Tynan, Art Armt

- Sgt John Loch , Art Armt

- Cpl Patrick Harris, Armourer

- Cpl Noel Newton, Armourer

- Cpl Robert Bradford, Armourer

- Cfn Richard (Sledge) Ammer, Armt Fitter

- Cfn Brian Carter, Armt Fitter

- Cfn Kevin Cuneo, Armt Fitter

- Cfn John Kimberley, Armt Fitter

- Cfn Jeff (Rembrant) Costello, Painter

-

HQ 1 ATF

- WO2 John (Tex) Ritters, Art Armt,

References

- AF C2119 Commanders Diary, 106 Fd Wksp RAEME. 1 Mar 71 to 30 Mar 71

- AF C2119 Commanders Diary, 106 Fd Wksp RAEME. 1 Apr 71 to 30 Apr 71

- AF C2119 Commanders Diary, 106 Fd Wksp RAEME. 1 May 71 to 31 May 71

- AF C2119 Commanders Diary, 106 Fd Wksp RAEME. 1 Jun 71 to 30 Jun 71

- History: 104th Field Battery, RAA, Vietnam 1968 -1969 & 1971 (http://12fieldregiment.com.history_104fdbty.htm)

- Email: John Sinclair/David Miller, 29 Aug 2006, 3:04 PM,

Re:”Back to the Heartland”. - National Archives of Australia: Series Details AWM298

(Footnotes)

1There was a lot more equipment that should have been scrapped instead of preserved and shipped home. E.g. on RTA at 3Base Wksp I was faced with over 20 siezed VW powered generators (obviously ran out of oil!) that had been preserved & shipped home to be condemned BER & sent to auction. And to find the Vietnamese tradesmen at 102 Fd Wksp stripping paint & rust from hand tools and wooden benches so they could be painted and returned to Australia was too much. A telephone call to Major Pat Ferguson at HQ AFV soon got us some technical direction on what equipment/stores should preserved & RTA’d

2My career has taught me that the old EME saying of “you f…! it and we fix it” can have bad results for RAEME if our members (all ranks too!) forget that a most important EME function is Technical Advice. If a user wishes to degrade equipment by overloading etc it then it is his responsibility but!! he must be made aware of the implications of his decision and we have that responsibility. Once having to sign off on the conversion of a million dollar plus lightweight aluminium bridge from an operational asset to a training aid (because of poor user maintenance) brought that home to me (and particularly to the owner CO!)

3 Obtaining volunteers for a bartering trip to the US Long Binh depot (28 km perimeter) was not a problem as personal trading could also be conducted. We set off after being amply supplied by the QM with GP Boots; Socks; Slouch Hats; Camouflage Raincoats and slabs of Aussie Beer paid for by ourselves. Being an honest officer and not wishing to get too involved in my soldiers sometimes dubious activities; I stayed with our hosts, the US Maintenance Coy in case higher rank help was needed to get one of our guys out of trouble. We left for the trip home with lots of gun parts; tyres for our M543 Wreckers (supposedly none in depot) etc and stopped outside the depot after the US MP’s checked us through. Sgt Tony Tratt RAAOC (Driving) stopped the stores truck complaining of a lack of power and found that he had a “borrowed” 1 Ton US trailer on tow because the diggers couldn’t fit any more stores on the truck. We also had the offer of an M2A2 SP Gun for our perimeter defence but John Sinclair didn’t think our neighbours or HQ 1ATF would approve.

4 For a given charge and shell, each individual gun will have a different muzzle velocity due to machining tolerances and wear. If the individual muzzle velocities are known then corrections can be calculated for each gun.

COMMENTS BY OTHER RAEME PERSONNEL

I asked Lt. Col. Jim Hislop who was then Lt. Jim Hislop the first OC GE Pl 106 Fd Wksp To comment:

They (M2A2) could have arrived earlier in Nov/Dec 66 but the Seaman's Union refused to load them on the Jeparit. There is no doubt the guns were purchased as second hand (maybe third hand as I recall being told some had been with the Canadian Army). I was attached to HQAFV from April 68 to Oct 68 and one of my tasks was to travel to Bein Hoa to remove parts from US unrepairable weapons in the "Use Again Park" and get them to the LAD, we found many of the parts were not compatible and at the time I wondered if the weapons as purchased were a combination of several marks of the same weapon.

Regards Jim

I asked also Lt.Col C.V.L. Palmer the second commander of 106Fd Wksp if he would comment.

Happy to help,

My previous posting was Deputy Asst Master of Ordnance, Directorate of Equipment. In 1967, our 105's were the Oto Melara pack howitzer. But when fired for any time on charge 6 bis, their elevating worm wheel would shear. Working with EDE, we solved the problem by inserting a torsion bar spring into the elevation shaft, so cushioning the recoil impact on the worm. In the meantime, D Arty had asked Ordnance to procure US 105 M2A2's. Most of these were used, and were later found to have recoil slide wear.

Later, as CO TSU in 1974, Sch of Arty CO 'Pinky' Salmon phoned me to the effect that his 'newly rebuilt' M2A2's were firing inconsistently in line. He said that neither his Art Gun nor local EIS could diagnose the prob. As the Sch was trialling TSU-initiated items- trilux sight illumination and the proj-cartridge aligner, I visited the Sch. Sure enough, the M2A2 seemed to have brand new ordnance, no rifling wear at all. But the muzzles could be moved by hand a good 20 mm sideways! Clearly, the local Arts had forgotten the Vietnam prob! Guess I would then have suggested that, after repair, the recoil slides should be kept lubed, maybe in an EMEI?

I also asked Major Ross Bland OC 12Fd. Regt RAA LAD to comment:

Gun Slides M2A2/ M2A1,May/Jun 1968 10Apr 68

By Major Ross Bland OC LAD 12 FD Regt.

Arrived Nui Dat with 12 Fd Regt LAD main body and commenced stocktake immediately ...

OC 4Fd Regt LAD advised that the 105 mm L 5 Guns had been replaced in total with M2A2/M2A1 Guns apparently sourced "IN COUNTRY" and NOT in NEW condition.

A cursory inspection of 102 ,104 and 161 Bty Guns and equipment was conducted on 12/13 Apr 68. Compared to 161 Bty Guns, the others seemed to be well worn and Not previously well maintained (by previous users ).

A good scaling of Repair parts for the LS Guns was still held by 4Fd Regt LAD although the L5 guns had long gone from Nui Oat (out scaling had not been conducted ).There was only a sparse holding of M2A2/M2A1 repair parts.

The LS parts had to be fully Documented and out scaled by the newly arrived 12FdRegt LAD storemen and transported to the ORO Depot Vung Tau .Experience with this depot showed that the system operators believed that the Repair Parts were interchangeable between the different Guns. This explained the shortage of M2A2/M2A1 parts. Additionally There had NOT been a usage forecast of Barrels and other MUA's. The OC 12 Fd Regt LAD was called to HQ AAFF (502 Ord )To clarify the situation. A forecast of barrels was submitted on return to NUl DAT.

4/5 Jun 68... The detailed inspection of Guns continued and the wear factor of the M2A2 cradle slides were· found to be beyond permissible wear Iimits(12 mm L&R) Test Firing was conducted by The Regt to document the effects on shooting if any! Defect /inspection reports were submitted.

9 Jun 68The OC 12 Fd Regt LAD was ordered to report to HQAAFF (501 EME ), he was placed under the escort of a junior Officer and sent to a prearranged meeting with an American Army M2A2 Gun Expert at Long Bin.

After the exchange of info and a good discussion, the American officer advised that he had been in a similar situation in Germany where people were Killed due to this same problem with slide wear.

This information was reported to the SO1 EME by my escorting Officer. I was later told that the slide repair may be an LAD task. This was rescinded,

(102Fd Wksp refused this Task and also the task of manufacturing Cross heads)

It was general talk after CORAL that the Gun Btys were Firing up to 500 rounds /night. This .would have exacerbated but notcaused the total wear of the slides. Obviously the slides -.were worn and maintenance was not of a high order when the Guns were initially delivered to 4Fd Regt RAA.

Soon after an engineering Officer from HQ EME (Albert Park Maj. C.V.L. Palmer) produced a maintenance procedure which required all Guns to be stripped to expose the Cradle and recoil slides. These were to be thoroughly cleaned free of dirt and dust, re-lubricated and the Gun reassembled after every Operation .This action was to be logged. This procedure was somewhat effective but could not compensate for the pre-existing wear.

UNAUTHORISED SPARE PARTS FOR TIRED AND WORN M2A2 HOWITZER

By WO1 Bob Thompson ASM

Early in 1969 the M2A2 105 Howitzers from 12 Fd Regt were showing extreme tiredness through excessive firing and lack of spare parts.

Early in 1969 the M2A2 105 Howitzers from 12 Fd Regt were showing extreme tiredness through excessive firing and lack of spare parts.

The ASM of 12 Fd Regt LAD WO1 John Bagnell was an old friend and at that time I was the ASM of 106 Fd Wksp when WO1 John Bagnell came to see me and asked me to AAF 406 (authority to replace an equipment) a M2A2 Howitzer. I of course asked him on what grounds was I supposed to use to write off the equipment and he told me the Breach itself was so worn that it was causing setback with the ammunition. ( It means the shell casing doesn’t go fully into the chamber)

I told him to bring over the gun and I would have a look at it. It arrived that afternoon. On inspection the cradle slides were well worn ( I was asked to ignore the cradle slides as they were aware of that problem BUT needed the gun) the Breach slides were worn and badly scored. There was no doubt the main reason for setback was a worn Breach that needed to be replaced. I raised an order and gave it to the Stores Officer to get a new breech from 2AOD Vung Tau.

Next day our stores Officer informed me there wasn’t any Breeches in country and from what we knew none available in country from the Americans nor back in Australia. I remembered when I was in EIS and inspecting 2AOD I happened to walk through the store house and I seen a Breech for a 105 How, so I told the Stores Officer to resubmit the order as I knew there was a Breech in the store. He did that and was told in no uncertain way that 2AOD had already said they didn’t have a Breech and that was that.

I grabbed the order form and a vehicle and drove straight down to Vung Tau and to 2AOD where I was friendly with a Sgt In the requisition section and told him he had a Breech in the store. He looked up his card records which stated there wasn’t any. I took him through the store and there in all it’s glory I showed him it. I got him to process the order, usually referred to as walking an order through and put the Breach in my vehicle and drove back to Nui Dat and 106.

We replace the breech and of course it’s breech Block and Cross Head and I then rang WO1 John Bagnell told him the story and to come and pick up their 105 How.

Next day there is hell to play from the CO of 2AOD who was most irate that some WO from 106 Fd Wksp had come down to his store and after being told they didn’t have a Breech, talked the Sgt store man into looking in the store house and taking a Breech out of his store through unusual circumstances and he wanted the ASM who got the Breech to be charged. Next thing I am up before my CO Maj. C.V.L. Palmer who wants to know on what authority I had to just go down to Vung Tau into the Ordinance Depot and take out a Breech. I explained the urgency that I was told by 12 Fd Regt LAD. Rotor Button gave me a lecture, tongue in cheek and told me not to do it again.